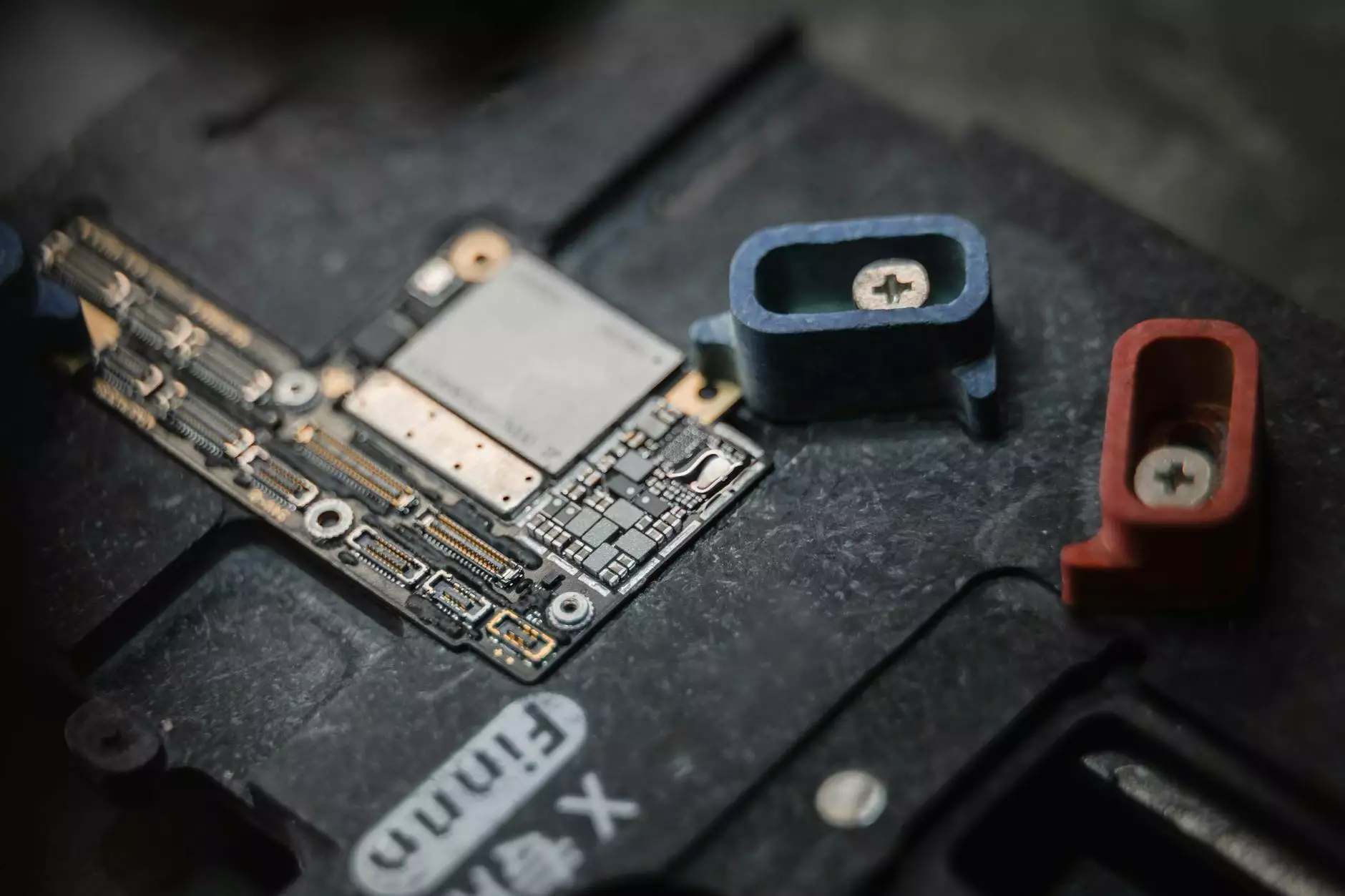

Discovering Titanium Screws Manufacturers: A Guide to Quality and Innovation

In today's manufacturing landscape, titanium screws hold a unique position due to their remarkable strength, low weight, and resistance to corrosion. This article aims to provide an in-depth exploration of the realm of titanium screws manufacturers, particularly in the context of sporting goods, outdoor gear, and bicycles.

The Importance of Titanium in Manufacturing

Titanium is well-known for its exceptional properties, making it a preferred material in various sectors. Its benefits include:

- Strength-to-weight ratio: Titanium is significantly lighter than steel yet equally strong, making it ideal for applications where weight savings are critical.

- Corrosion resistance: It withstands harsh environments, which is crucial for outdoor and marine applications.

- Durability: Products made from titanium offer long-lasting performance under extreme conditions.

Why Choose Titanium Screws?

When looking into the offerings of various titanium screws manufacturers, it's vital to understand why titanium screws are prized across industries. Here are some compelling reasons:

1. Enhanced Performance in Sporting Goods

In sporting goods, every ounce counts. Athletes and enthusiasts alike are increasingly opting for titanium screws due to their ability to reduce the overall weight of equipment without compromising strength. For instance:

- Golf clubs: Manufacturers are using titanium screws in club heads to optimize their performance.

- Camping gear: Titanium is integrated into camping cookware, where lightweight yet strong screws secure parts and components.

2. Durability for Outdoor Gear

Outdoor gear must withstand the elements, and titanium screws are up to the challenge. Their resistance to rust and corrosion makes them perfect for:

- Tents: The durability of titanium screws in tent poles ensures that outdoor enthusiasts are secured even during inclement weather.

- Backpacking equipment: Lightweight yet durable screws reduce the overall pack weight while providing the necessary strength.

3. Innovation in Bicycle Manufacturing

The bicycle industry has also embraced titanium, with rims, frames, and components becoming lighter and stronger thanks to titanium screws. Key advantages include:

- Improved aerodynamics: Every gram saved contributes to a bike's performance, making titanium screws a favorite among competitive cyclists.

- Long-lasting quality: Titanium's endurance means fewer replacements, thus enhancing cost-effectiveness in the long run.

Choosing the Right Titanium Screws from Manufacturers

With numerous titanium screws manufacturers in the market, selecting the right one can be daunting. Consider the following factors:

1. Quality Assurance

Before purchasing, check if the manufacturer adheres to quality standards. Certificates such as ISO 9001 indicate a commitment to quality management.

2. Variety of Products

Different applications require various types of screws. A versatile manufacturer will offer:

- Coarse and fine thread options

- Diverse head types (button, flat, socket, and more)

- Custom sizes and lengths

3. Pricing Structure

While titanium screws are generally more expensive than their steel counterparts, check for suppliers who offer competitive pricing without compromising quality.

Top Titanium Screws Manufacturers to Consider

When searching for reliable suppliers, consider some of the leading titanium screws manufacturers known for their high-quality products:

1. TitaniumBolts.com

TitaniumBolts.com specializes in high-performance titanium screws tailored for sporting goods, outdoor sports, and bicycles. Their commitment to quality and customer satisfaction makes them a preferred choice for many.

2. Titanium Industries, Inc.

As a well-established provider, Titanium Industries offers a wide range of titanium products, including screws that meet the needs of diverse industries. They focus on customer service and fast delivery.

3. Fastenal

Fastenal combines quality with availability, making it easy for businesses needing titanium screws quickly. Their inventory includes various sizes and types specifically for outdoor gear and bicycles.

Future Trends in Titanium Screw Manufacturing

The market for titanium screws is evolving, driven by advancements in technology and increased demand. Some trends to watch include:

1. Sustainability in Manufacturing

As environmental concerns grow, manufacturers are exploring sustainable practices, such as recycling titanium to reduce waste and environmental impact.

2. Additive Manufacturing

3D printing is making waves in the manufacturing sector, allowing for custom and intricate designs in titanium screws that can save materials and reduce costs.

3. Enhanced Coatings

Innovative coatings are being developed to enhance the properties of titanium screws, improving their performance in specific environments and extending their lifespan.

Conclusion

In conclusion, the realm of titanium screws manufacturers is rich with opportunities and advancements that cater to a wide array of industries, especially sporting goods, outdoor gear, and bicycles. By embracing the unique properties of titanium, manufacturers can deliver products that are lightweight, durable, and corrosion-resistant. Whether you are a manufacturer, retailer, or final user, understanding the benefits of titanium screws will undoubtedly assist in making informed decisions for a brighter, more innovative future in your projects.

For more information and inquiries, do not hesitate to reach out to TitaniumBolts.com where you can access a range of high-quality titanium screws tailored to your needs.