Unlocking Excellence in Metal Fabrication & Plastic Injection Molds: Your Partner in Precision Manufacturing

Introduction to Metal Fabrication and Plastic Injection Molds

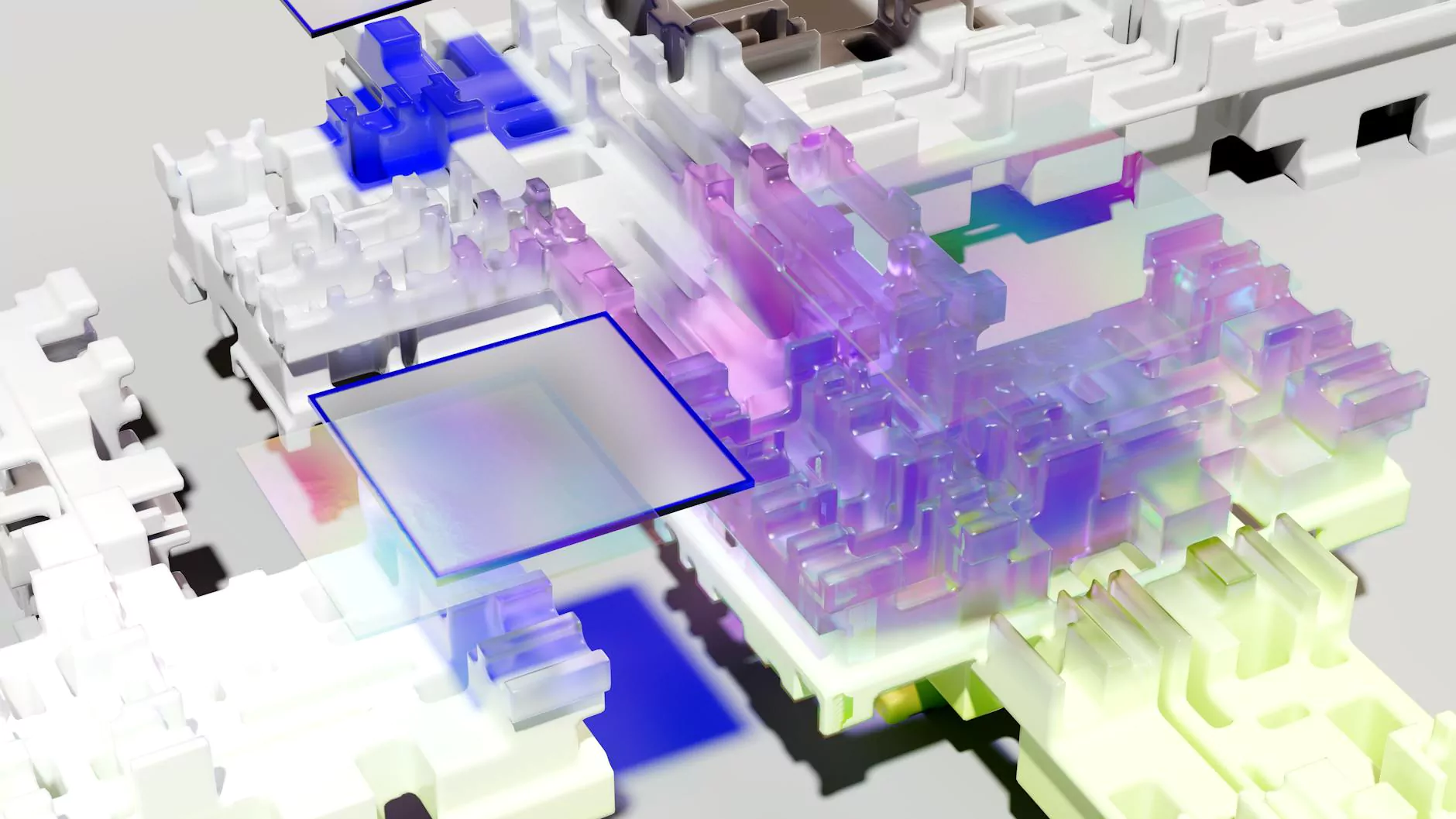

In today’s rapidly evolving manufacturing landscape, the importance of high-quality metal fabrication and precise plastic injection molding cannot be overstated. These industries form the backbone of countless sectors, including automotive, consumer electronics, healthcare, and industrial equipment. Companies like Deep Mould stand at the forefront, providing comprehensive services that satisfy the stringent demands of modern manufacturing.

As a seasoned metal fabricator and a renowned plastic injection mold manufacturer, Deep Mould leverages cutting-edge technology, advanced materials, and a team of highly skilled engineers to deliver solutions that are not only reliable but also innovative and cost-effective. Whether you are developing a prototype or managing large-scale production, understanding the intricacies of metal fabrication and injection molding is essential for achieving excellence.

The Significance of High-Quality Metal Fabricators in Modern Industry

What Is Metal Fabrication?

Metal fabrication involves transforming raw metal materials into finished products through various processes such as cutting, bending, welding, and assembling. This process is fundamental for creating structural components, enclosures, frames, and intricate mechanical parts.

Why Choose Professional Metal Fabricators?

- Precision & Accuracy: High-end metal fabricators utilize sophisticated machinery like CNC machines and laser cutters to achieve exact measurements and intricate designs.

- Material Diversity: From stainless steel and aluminum to copper and alloys, reputable fabricators work with a wide range of metals tailored to application needs.

- Cost Efficiency: Optimized processes reduce waste and labor costs, offering competitive pricing without compromising quality.

- Customization Capabilities: Advanced fabrication technologies enable creating bespoke solutions flawlessly aligned with client specifications.

Applications of Metal Fabrication

Industries depend on metal fabrication for numerous critical components, including:

- Automotive chassis and body parts

- Architectural structures and decorative elements

- Electrical enclosures and control panels

- Medical devices and laboratory equipment

- Industrial machinery components

Deep Mould’s expertise in high-precision metal fabrication ensures that every project meets the rigorous standards of durability, functionality, and aesthetic appeal necessary across sectors.

Understanding the Role of Plastic Injection Mold Manufacturers in Manufacturing Efficiency

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where molten plastic is injected into precision-engineered molds to produce complex and detailed parts. It is highly valued for its ability to produce large volumes of consistent, high-quality components efficiently.

The Importance of Quality in Plastic Injection Molds

- Dimensional Accuracy: High-precision molds ensure every plastic part adheres to tight tolerances, critical for functional assembly.

- Surface Finish: Quality molds produce smooth surfaces that reduce post-processing requirements and improve aesthetic appeal.

- Cycle Time Optimization: Well-designed molds minimize cycle times, increasing production efficiency.

- Durability & Longevity: Premium molds withstand high-volume runs without degradation, reducing overall tooling costs.

Choosing the Right Plastic Injection Mold Manufacturer

Partnering with an experienced plastic injection mold manufacturer like Deep Mould guarantees access to advanced technology, meticulous quality control, and tailored solutions. Factors to consider include:

- Technical expertise and experience with diverse plastics and complex geometries

- Availability of state-of-the-art CNC machining, EDM, and other tooling technologies

- Robust quality assurance protocols including 3D inspections and surface analysis

- Competitive pricing combined with timely delivery

Industries that Rely on Plastic Injection Molds

- Electronics: Smartphone casings, connectors, and micro-components

- Automotive: Interior panels, bumpers, and lightweight structural parts

- Consumer Goods: Toys, household appliances, and personal care devices

- Medical Devices: Surgical tools, diagnostic equipment, and disposables

- Packaging: Bottles, caps, and container components

Deep Mould excels in delivering customized injection molds tailored to meet unique industry and client-specific requirements, reinforcing its position as a trusted partner for businesses aiming for manufacturing excellence.

Synergy Between Metal Fabrication & Plastic Injection Molding in Modern Manufacturing

While each process caters to different materials and end-products, synergistic integration of metal fabrication and plastic injection molding enhances manufacturing efficiency and product innovation. For example:

- Metal components serve as frames, housings, or structural support within plastic assemblies.

- Injection-molded plastic parts can incorporate metal inserts for added strength and durability.

- Prototyping and low-volume production often combine both processes to rapidly develop complex assemblies.

Businesses like Deep Mould leverage their expertise in both fields to create comprehensive solutions that streamline production, reduce costs, and improve product performance.

The Advantages of Partnering with a Leading Manufacturer Like Deep Mould

Unparalleled Quality & Precision

Deep Mould’s commitment to quality is reflected in their rigorous quality control protocols, advanced machinery, and skilled workforce. This ensures that every metal fabrication and plastic injection mold meets stringent standards, delivering consistent, reliable, and high-performance products.

Innovative Design & Engineering

The company employs cutting-edge CAD/CAM software and simulation tools to optimize designs before manufacturing, reducing risks and enhancing functionality.

Comprehensive Service Offering

- Design consultation and prototype development

- Material selection guidance based on application needs

- Fabrication and assembly of metal components

- Design and production of injection molds

- Mass production and quality assurance

Cost-Effectiveness & Timely Delivery

Through process optimization, bulk purchasing, and efficient project management, Deep Mould ensures competitive pricing and on-time delivery, helping clients stay ahead in competitive markets.

Customer-Centric Approach & Technical Support

Deep Mould places a strong emphasis on collaboration, providing technical support and customization options at every stage of the project lifecycle, ensuring tailored solutions that meet exact specifications.

Innovation and Future Trends in Metal Fabrication & Plastic Injection Molding

The future of metal fabrication and plastic injection molding lies in technological innovation, sustainable manufacturing, and smart automation. Leading companies are exploring:

- Automation & robotics: Increasing productivity and precision with intelligent automation systems.

- Advanced Materials: Using composite materials, biodegradable plastics, and heat-resistant alloys for specialized applications.

- Sustainable Practices: Reducing waste, recycling materials, and minimizing environmental impact.

- Digitalization & IoT: Implementing Industry 4.0 principles for real-time monitoring and process optimization.

- Additive Manufacturing: Complementing traditional methods with 3D printing for rapid prototyping and complex geometries.

By staying at the forefront of these trends, Deep Mould continues to provide innovative, eco-friendly, and efficient manufacturing solutions that meet the evolving needs of global industries.

Conclusion: Your Trusted Partner in Manufacturing Innovation

In an era where precision, quality, and innovation are crucial, choosing the right partner for metal fabrication and plastic injection mold manufacturing makes all the difference. Deep Mould stands out with its comprehensive capabilities, commitment to excellence, and customer-first approach. By harnessing the latest technologies and industry best practices, they enable businesses to realize their product visions with confidence.

Whether you require intricate metal fabrications or highly detailed plastic injection molds, Deep Mould is your ultimate partner for transforming ideas into reality. Trust in their expertise to elevate your manufacturing process and achieve superior results that surpass expectations.

Contact Deep Mould Today for Outstanding Metal & Plastic Manufacturing Solutions

Explore how Deep Mould’s expertise can support your business growth. Reach out for consultations, quotes, and project discussions. Elevate your manufacturing with a partner dedicated to quality, innovation, and excellence in metal fabrications and plastic injection molds.